Exploring Surface Finishes for PCBs

Why FlashPCB Chooses ENIG for Optimal Flatness

When it comes to Printed Circuit Boards (PCBs), the surface finish plays a crucial role in ensuring reliability, performance, and manufacturability. FlashPCB understands the importance of selecting the right surface finish, which is why we default to using Electroless Nickel Immersion Gold (ENIG) for its superior flatness for our 5 and 10 day lead times, and default to Hot Air Solder Leveling (HASL) for our 3 day orders for its fast processing time . In this blog post, we'll delve into the different types of surface finishes available for PCBs, their advantages, and why ENIG stands out as the preferred choice for FlashPCB.

When it comes to Printed Circuit Boards (PCBs), the surface finish plays a crucial role in ensuring reliability, performance, and manufacturability. FlashPCB understands the importance of selecting the right surface finish, which is why we default to using Electroless Nickel Immersion Gold (ENIG) for its superior flatness for our 5 and 10 day lead times, and default to Hot Air Solder Leveling (HASL) for our 3 day orders for its fast processing time . In this blog post, we'll delve into the different types of surface finishes available for PCBs, their advantages, and why ENIG stands out as the preferred choice for FlashPCB.

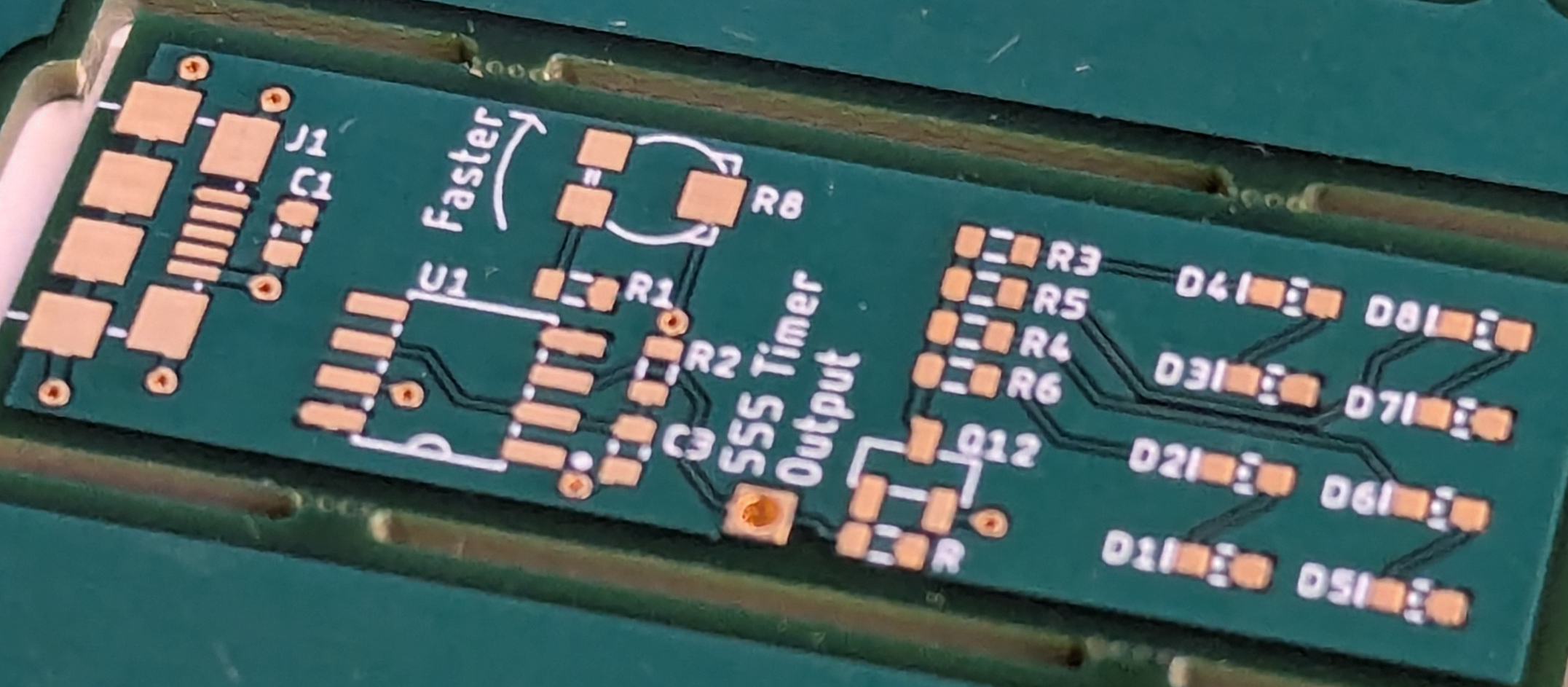

What is a PCB Surface Finish?

A PCB surface finish is a coating applied to the exposed copper areas of a PCB to protect it from oxidation and ensure solderability during the assembly process. The choice of surface finish can impact the PCB's longevity, electrical performance, and overall assembly quality. Let’s explore the most common types of PCB surface finishes. Types of PCB Surface Finishes

Hot Air Solder Leveling (HASL)

HASL is one of the most traditional surface finishes, where the PCB is dipped in molten solder, and excess solder is removed by hot air knives. Traditional HASL uses a tin-lead alloy, while lead-free HASL uses alternative alloys such as tin-silver-copper (SAC).

Advantages:

- Cost-effective

- Good shelf life

- Provides a strong solder joint

- Fast Processing

Disadvantages:

- Uneven surface, not ideal for fine-pitch components

- Thermal stress during the process can damage the board

Organic Solderability Preservative (OSP)

OSP is an organic coating applied to protect copper pads from oxidation. The organic compound typically used is an azole derivative, most commonly benzotriazole (BTA), imidazole or benzimidazole. These compounds chemically bond to the copper surface,the specific type of azole used can vary based on the desired properties and application requirements.

Advantages:

- Environmentally friendly

- Low cost

- Flat surface, suitable for fine-pitch components

Disadvantages:

- Limited shelf life

- Sensitive to handling and storage conditions

- Not suitable for multiple reflow cycles

Electroless Nickel Immersion Gold (ENIG)

ENIG is a two-layer metallic coating with a layer of nickel covered by a thin layer of gold. The process begins Electroless Nickel plating where a layer of nickel is chemically deposited onto the exposed copper surfaces of the PCB . This nickel layer acts as a barrier to prevent copper migration and provides a smooth surface for soldering. Following the nickel application, a thin layer of gold is deposited over the nickel through an immersion process. The gold layer protects the nickel from oxidation and ensures excellent solderability.

Advantages:

- Excellent flatness, ideal for fine-pitch and BGA components

- Good shelf life and corrosion resistance

- Superior solderability and electrical performance

Disadvantages:

- Higher cost compared to HASL

- Risk of "black pad" issues if not applied correctly

Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG)

ENEPIG adds an additional palladium layer between the nickel and gold layers.

Advantages:

- Excellent for wire bonding and multiple reflow cycles

- Superior corrosion resistance

- Provides a strong, reliable solder joint

Disadvantages:

- Higher cost due to additional palladium layer

- More complex manufacturing process

Immersion Tin

Immersion Tin is a metallic finish where a thin layer of tin is deposited on the copper pads. It is also known as “white tin” as the tin plating can appear white. The PCB is cleaned and micro-etched to roughen the exposed copper surfaces. The PCB is then immersed in a solution the typically contains stannous ions and an acid that facilitates the plating reaction.

Advantages:

- Flat surface, suitable for fine-pitch components

- Good solderability

- Relatively low cost

Disadvantages:

- Limited shelf life

- Potential for whisker growth

- Requires careful handling and storage

Why FlashPCB Defaults to ENIG for 5 and 10 day lead time orders

At FlashPCB, we prioritize quality, reliability, and performance in our PCB assembly services. Here’s why ENIG is our default choice:

- Superior Flatness: ENIG provides an exceptionally flat surface, crucial for assembling fine-pitch and BGA components with precision.

- Excellent Solderability: The gold layer ensures a reliable solder joint, enhancing the overall performance and longevity of the PCB.

- Versatility: ENIG is suitable for a wide range of applications, from consumer electronics to industrial and automotive sectors.

- AI-Powered Precision: Our AI-powered assembly process benefits from the consistent quality of ENIG finishes, reducing defects and improving yield rates

Choosing the right surface finish is vital for the performance and reliability of PCBs. While each finish has its own set of advantages and challenges, ENIG stands out for its excellent flatness, solderability, and corrosion resistance, making it the preferred choice for FlashPCB. By leveraging our AI-powered assembly service with the superior quality of ENIG finishes, we ensure that our customers receive the best possible PCBs for their applications.

Newsletter

For more information sign up at here.