In-House X-Ray Inspection: Detecting Bridging, Voids, and Missing Balls

How Advanced X-Ray Technology Ensures Superior Reliability and Performance in PCB Assemblies

To better guarantee the quality of the PCB assemblies we produce, we have added in-house x-ray capabilities. For many components, a visual inspection is sufficient to determine the quality of the solder joints. However, with Ball Grid Arrays (BGAs), Quad Flat No-lead (QFN) packages, or Land Grid Arrays (LGAs), these joints are hidden under the component.

X-ray inspection uses high-energy photons to penetrate PCB assemblies, creating detailed images of their internal structures. This process provides several advantages:

- Non-Destructive: It allows for thorough inspection without damaging the PCB.

- High Resolution: It reveals fine details that other inspection methods might miss.

- Comprehensive Analysis: It can detect a wide range of defects, ensuring the overall quality and reliability of the PCB.

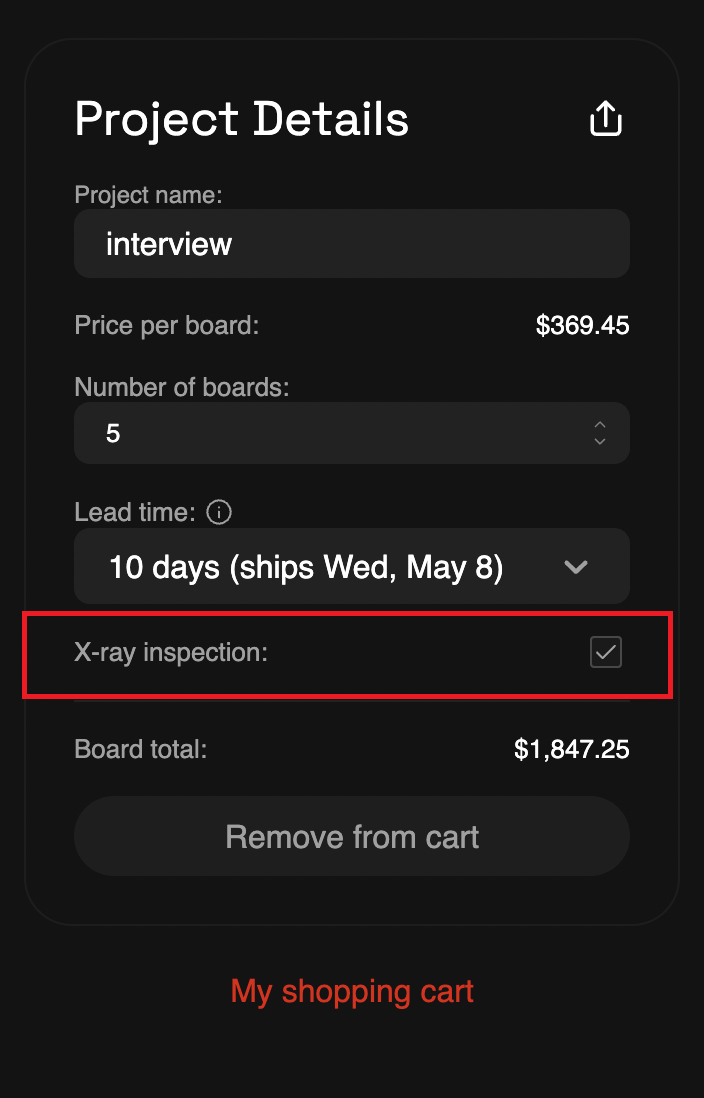

How to Order

-

Select X-Ray inspection in the Project detail window.

-

If there are specific components you would like images of, please email us at quote@flashpcb.com with the reference designator and order number.

Types of Defects

There are several types of defects we explicitly look for during x-ray inspection.

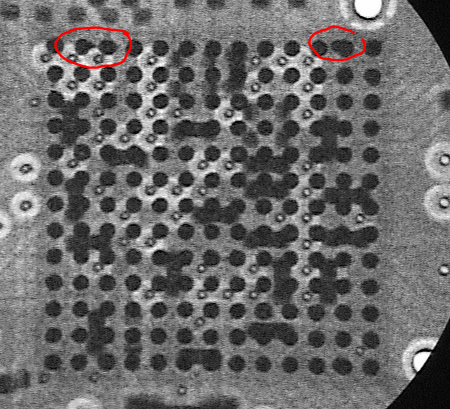

Bridges

Bridging occurs when solder creates an unintended connection between two or more adjacent conductive paths. This defect can cause short circuits, leading to the malfunctioning of the electronic device.

X-ray inspection can easily detect bridging by providing a clear view of the internal solder connections. The high-resolution images reveal any unintended connections between conductors, allowing for prompt identification and correction of the defect.

The balls in the red circles are potentially bridged together.

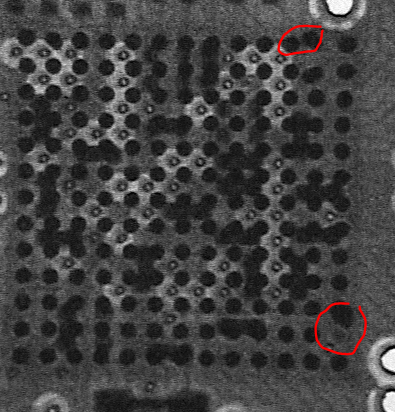

Voids

Voids are air pockets or gaps that occur within the solder joints. They can compromise the mechanical strength and electrical conductivity of the connections, potentially leading to failures in the PCB.

X-ray inspection can identify voids by revealing variations in density within the solder joints. The imaging technology highlights these gaps, making it easier to locate and assess their impact on the PCB's performance.

The lighter areas of the exposed pad of the QFN are voids. While the IPC-A-610 standard typically allows up to 25% voiding, there are many applications with a lower tolerance.

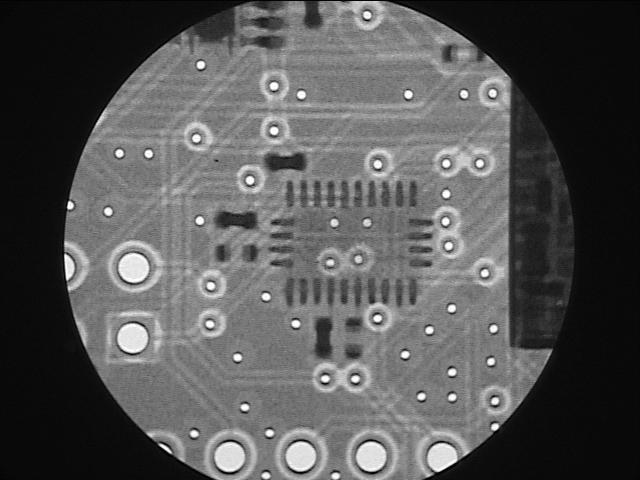

Missing or Displaced Balls

Missing balls refer to the absence of solder balls in Ball Grid Array (BGA) components. Displaced balls refer to the movement of one of the solder balls in a BGA away from its intended pad. When a ball is missing, the missed connections can lead to incomplete electrical circuits, resulting in device failure. When a ball is displaced, this can lead to short circuits in addition to the incomplete electrical circuit.

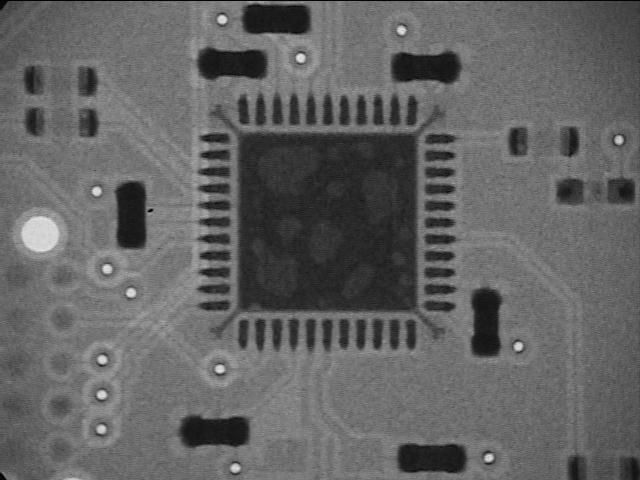

X-ray inspection provides a detailed view of BGA components, allowing for the detection of any missing or displaced solder balls. The high-resolution images clearly show the presence or absence of each solder ball, ensuring complete and accurate connections.

The ball in the top right of this BGA has been displaced from its intended pad, while the ball on the bottom right is missing.

More Information

For more information, please sign up for our newsletter or contact us here.